There exists today a wide variety of wood polymer composite boards that are commonly called "particle board". Basically these materials are made from nonchemically processed dry wood particles of various shapes and sizes and either synthetic or natural adhesive material. There are some specific cases and areas of research where the wood material is chemically treated to create greater compatibility between the wood and the polymer adhesive but to date are not a large portion of commercially produced "particle board".

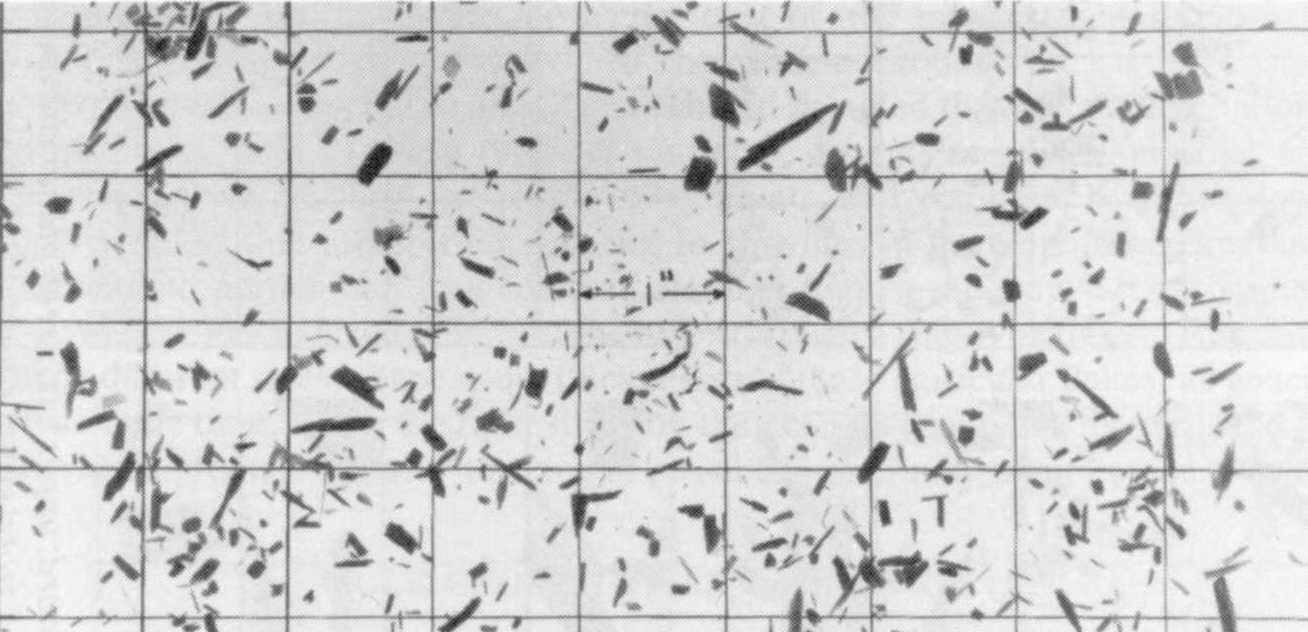

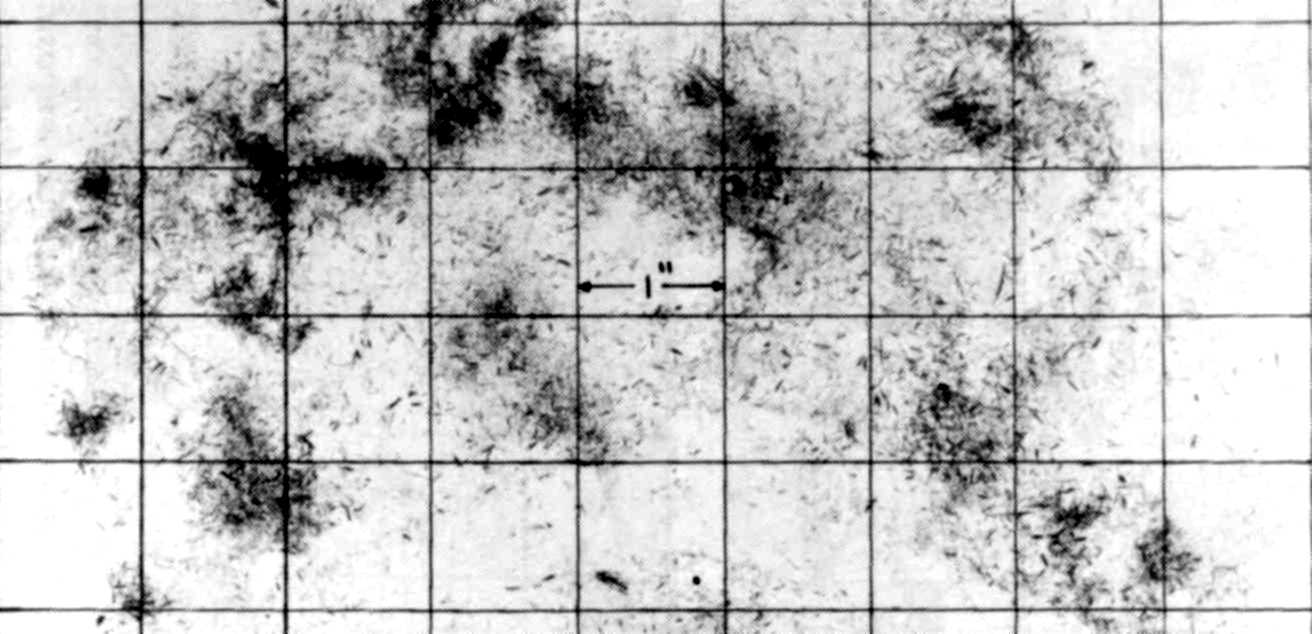

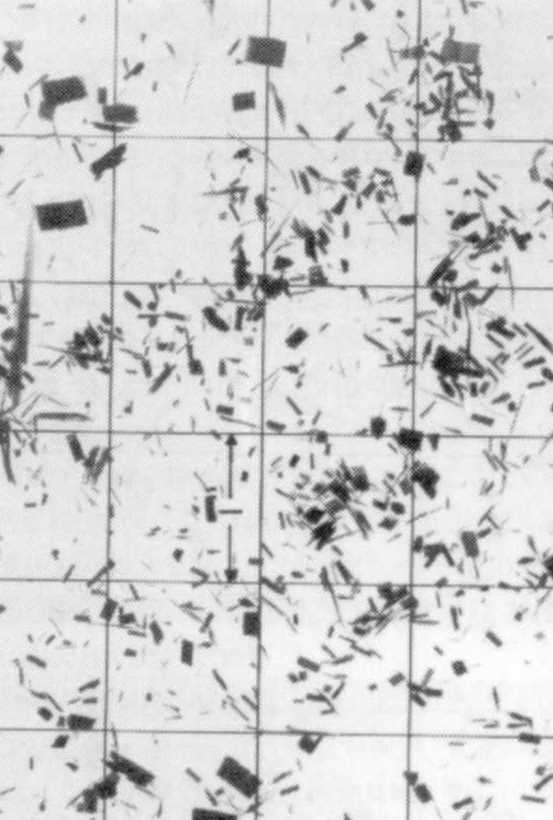

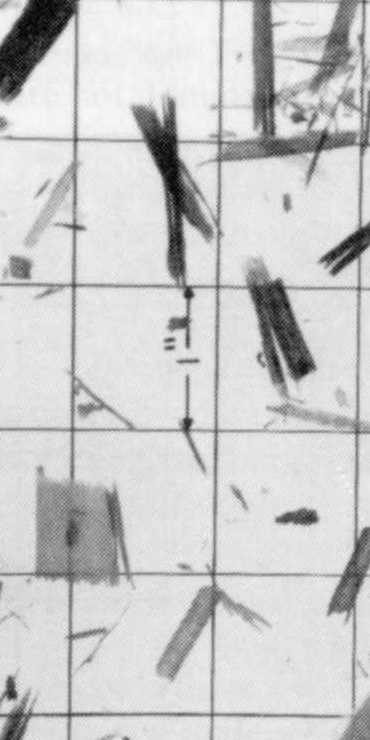

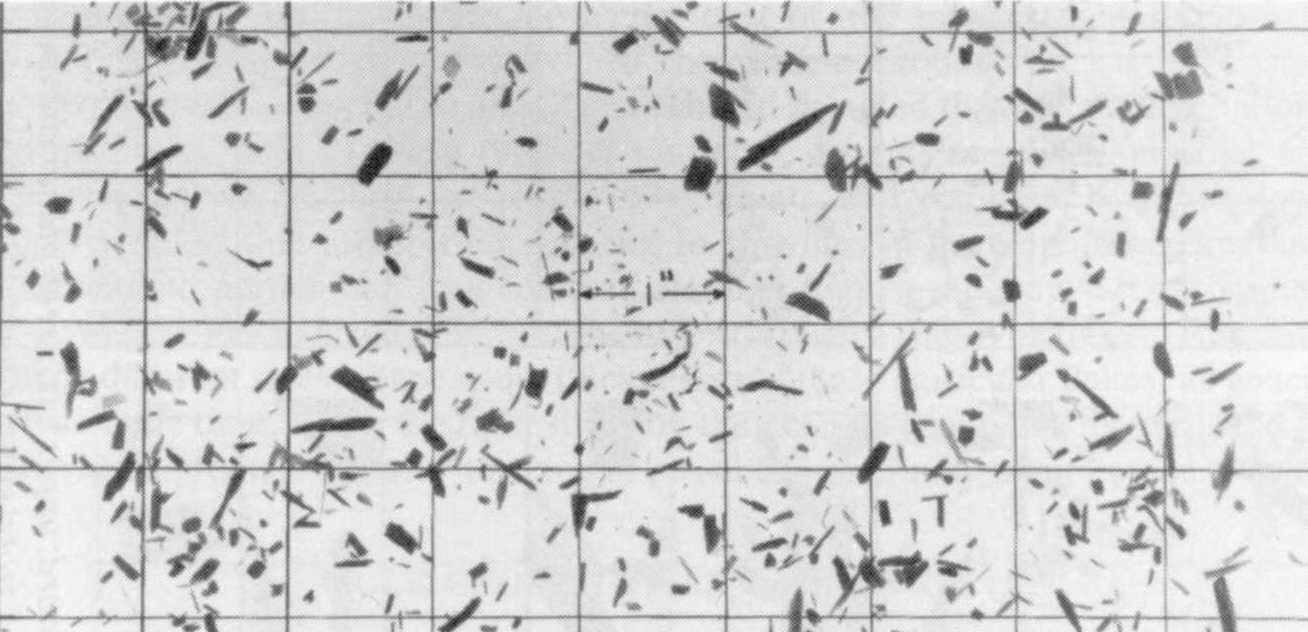

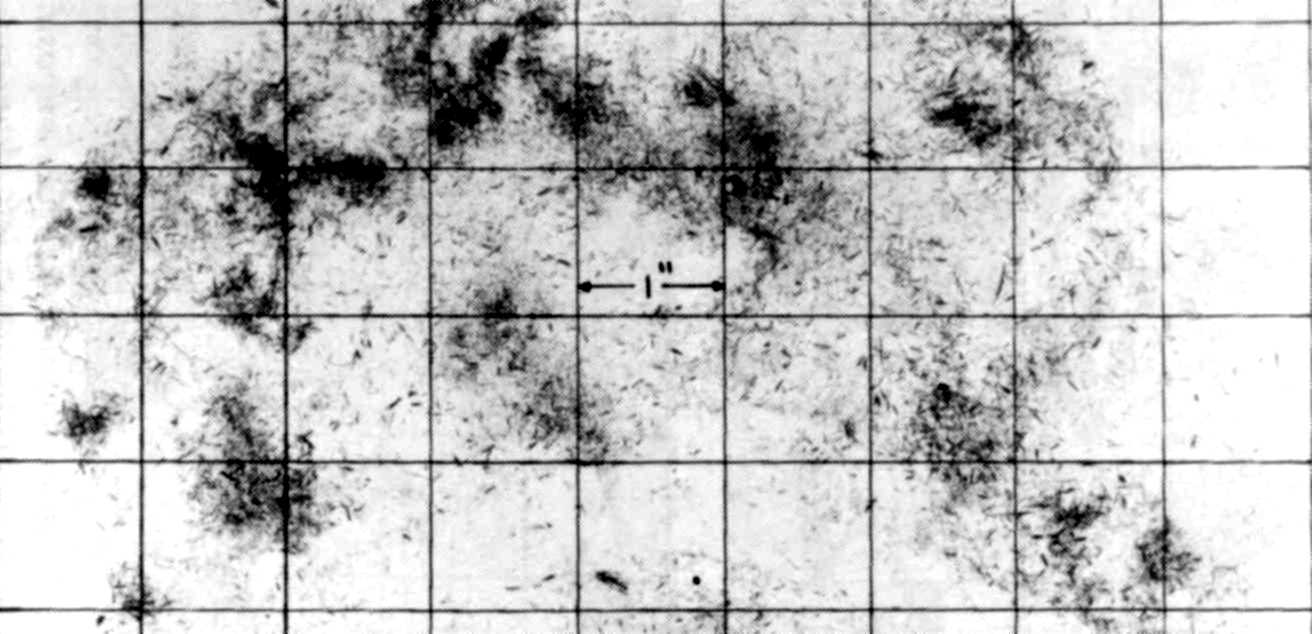

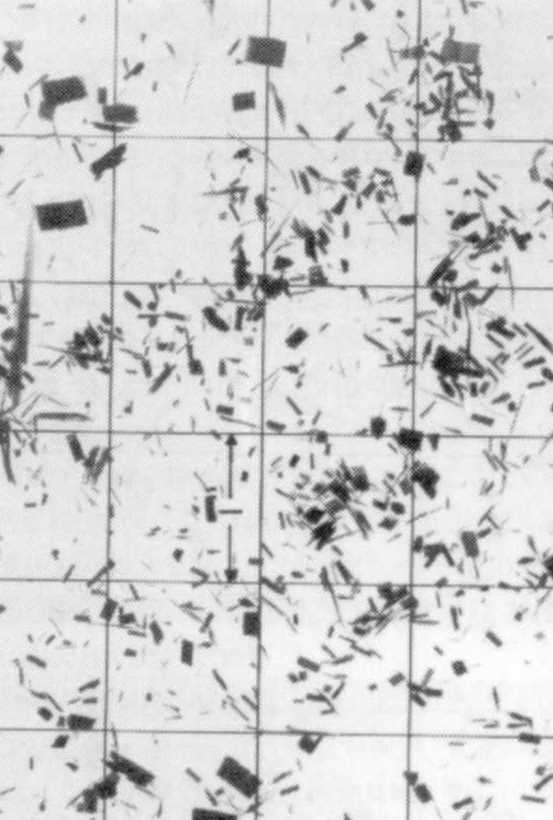

The basic materials from which particle boards are made can be broken down into four basic types.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

There are other types of ligno-cellulosic materials that are used in wood polymer composite materials that sometimes are lumped in with particle boards but differ mainly in the amount of processing involved in preparing the woody material for composite manufacture. Fiberboard is a good example in that the degree of fiberization is much higher than the above materials through chemical and physical treatment. Also non wood sources of cellulosic materials have been utilized to make these types of materials.

The described wood materials above are then bound together with thermosetting resins like phenol-formaldehyde, and other organics such as polyisocyanates

To learn more about particle board manufacture click here.