Polycarbonate is a clear plastic used to make shatterproof windows, lightweight eyeglass lenses, and such. General Electric makes this stuff and sells it as Lexan®. Polycarbonate gets its name from the carbonate groups in its backbone chain.

Another polymer used for unbreakable windows is poly(methyl methacrylate).

There's also another type of polycarbonate different from the one shown above. Some of us look at it all the time, because the lenses in our glasses are made out of it! These ultra-light polymer lenses are great for people with strong glasses that would be very heavy if they were made out of glass. Another thing that makes them lighter is that they refract or bend light better, so they are thinner than glass lenses. So because of polymers, people with strong glasses don't have to get headaches from wearing heavy lenses.

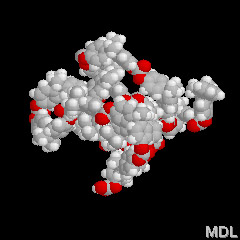

Below is a picture of it.

We make it by starting with this monomer:

And here is the final polymer when all the monomers get together and crosslink:

As you can see, the carbonate-containing groups (shown in blue) form the crosslinks between the polymer chains (shown in red). This crosslinking makes the material very strong, so it won't break nearly as easily as glass will. This is really great for anyone who has ever broken their glasses!

There is an important difference in the two types of polycarbonate described here. Polycarbonate of bisphenol A - the kind Lexan is made from - is a thermoplastic. This means it can be molded when it is hot. But the polycarbonate used in eyeglasses is a thermoset. Thermosets do not melt, and they can't be remolded. They are used to make things that need to be really strong and heat resistant.

| Other polymers used as plastics include: | Other polymers used as thermosets include: |

| Polypropylene | Epoxy Resins |

| Polyesters | Polyurethanes |

| Polystyrene | |

| Polyethylene | |

| PVC | |

| Nylon | |

| Poly(methyl methacrylate) |

|

Return to Kinds of Polymers |

|

Return to Main Page |