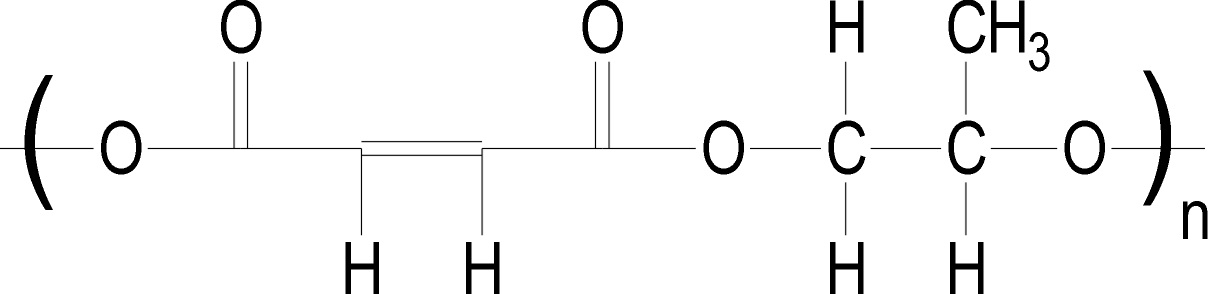

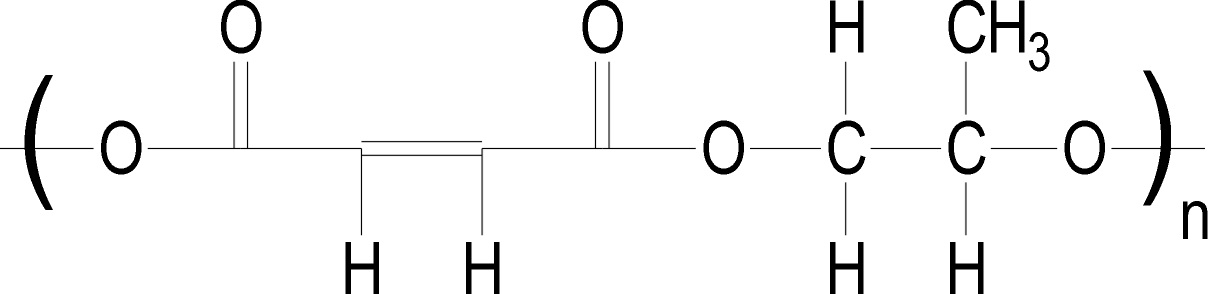

This is the repeat unit of PPF. Essentially it is an unsaturated polyester.

Bone-cartilage composite structure have been made by seeding chondrocytes and periosteal cells on to polymers. Also these types of materials have been made by suturing together cell-polymer scaffolds that have been seeded with bone producing cells.

Applications of these types of materials can be used as a bone cement that gives both structural integrity to a break and a scaffold for the seeded cells to grow. It is of course necessary that the polymer be gradually absorbed by the body overtime such that the bodies weight be shifted to the healing bone.

Bone cements utilized in repair of fractures unable to heal on their own should be both osteoinductive as well as osteoconductive. Osteoinductive refers to the materials ability to induce bone cell growth and osteoconductive means able to provide a path for the growing tissues.

For example Poly(propylene fumarate) (PPF) has been studied in these types of applications to replace the nondegradable poly(methylmethacrylate) bone cements used previously.

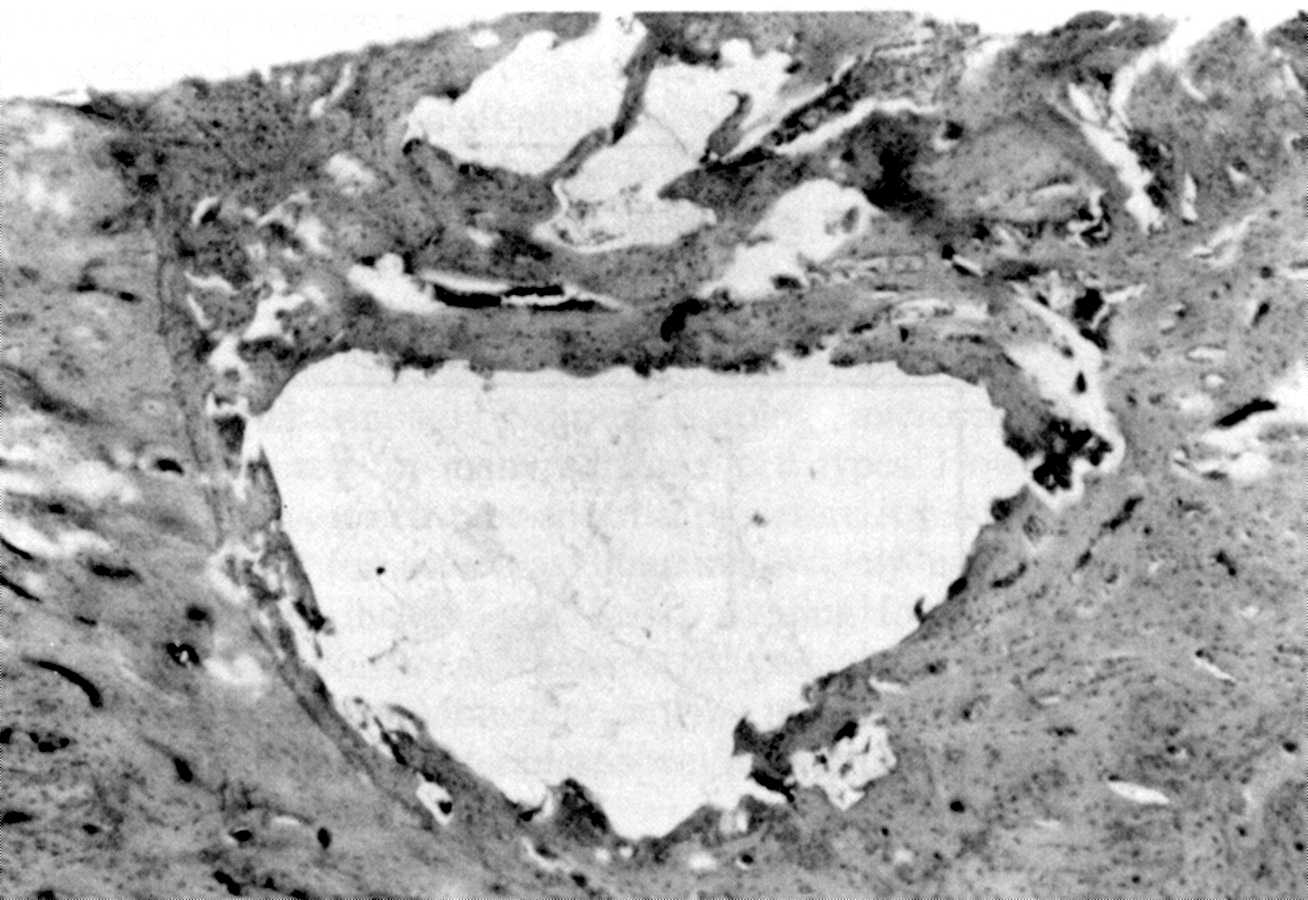

PPF is mixed with a cross linking agent and then injected into a fracture and cured in place. PPF has been injected into rat tibial defects and was shown to be bioconductive as one can see in the following picture.

The

white material is the polymeric material and the darker regions are bone

tissue. The important thing to note is that the bone tissue can be

seen to be growing throught the polymeric material towards the center.

This material is an example of a osteoconductive material. This type of bone cement may help in load bearing and conductance of new tissue but does nothing to enhance bone growth. In order for a polymer/tissue composite to be osteoinductive (material that induces bone growth.) has to be treated with a component that stimulates bone growth.

To see how this is done click here.