Interlaced mat of wood flakes.

Wet process fiberboard is basically made by making a slurry of wood fibers and in a controlled process laying it down on a screen which yields a damp matt of interlaced fibers as seen below.

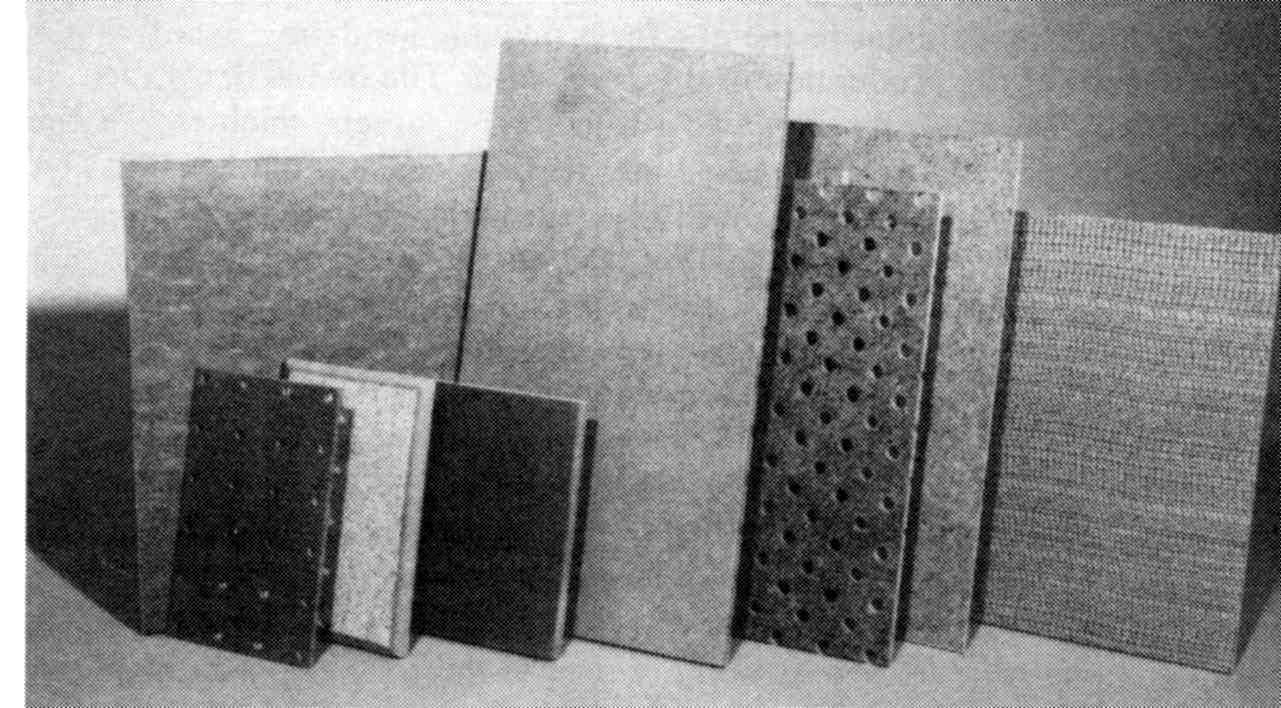

The material is then dried in a oven and sheets of material were thusly obtained as can be seen below.

These materials are used in sheathing, interior paneling, rigid roof insulation, and sometimes as siding. The advantages of this material are, You guessed it!!! Cheap!!!. Higher quality materials of this sort are made sometimes with the addition of polymeric adhesives. An extension of this process led to the invention of Masonite acommon hardboard used in a variety of construction applications.