Blowing bubbles is fun - seeing how far they'll go, with some floating up, some sideways, some down, and trying to catch them without making them pop. Chances are, you made the bubbles by blowing air into a film of soapy water.

Blowing bubbles is fun - seeing how far they'll go, with some floating up, some sideways, some down, and trying to catch them without making them pop. Chances are, you made the bubbles by blowing air into a film of soapy water.

Blowing bubbles is fun - seeing how far they'll go, with some floating up, some sideways, some down, and trying to catch them without making them pop. Chances are, you made the bubbles by blowing air into a film of soapy water.

Blowing bubbles is fun - seeing how far they'll go, with some floating up, some sideways, some down, and trying to catch them without making them pop. Chances are, you made the bubbles by blowing air into a film of soapy water.

If you put a straw into a cup of soapy water and blow bubbles, you can make a foam, but it doesn't last very long. (Whatever you do, don't breathe IN while you do this! Yuck!)

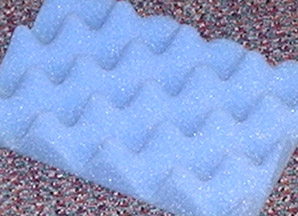

To make polymer foams, it's the same idea - there's a polymer that's soft (or in solution), and a lot of gas (usually not air) that's blown in to make a whole bunch of tiny little bubbles - a foam. The big difference is that the polymer bubbles will stay.

To make polymer foams, it's the same idea - there's a polymer that's soft (or in solution), and a lot of gas (usually not air) that's blown in to make a whole bunch of tiny little bubbles - a foam. The big difference is that the polymer bubbles will stay.

The gas that's blown in to make the foam is called a "blowing agent" or "foaming agent." (No, I'm not making this up!) The best kind of gas to use is one that won't react with anything, especially with the polymer, will be fire-resistant, and will be nontoxic. Nontoxic is important not only for the folks who make these foams, but for whoever buys them. That's because in many products, this gas stays in the little "cells", or bubbles, but after a while, they make their way out (that's called "degassing"). If we have a foam cushion, or any other foam that will be in our house, it needs to be safe (and fire-resistant is great, too).

The amount of gas, or foaming agent, used controls the size and the number of the bubbles, known as "foam cells" after it hardens.

Also, all of those little air bubbles make a great insulator for hot and cold items. StyrofoamTM is a popular brand of polystyrene foam, and it's used to make inexpensive coolers as well as cups.

Also, all of those little air bubbles make a great insulator for hot and cold items. StyrofoamTM is a popular brand of polystyrene foam, and it's used to make inexpensive coolers as well as cups.

There's also a way that foams can be created and molded at the same time, called (are you ready for this?) foam molding. This technique is great for large parts that need to be light, but stiff. Typical products are large trash containers, freeway sand safety containers, and in-ground housings for water systems.

|

Return to Making Stuff |

|

Return to Main Page |