For all you destruction freaks out there, it is finally time to drop the hammer, literally. ASTM Impact tests is a procedure for rapidly and magnificently deforming by hitting a coating film and substrate (metal panel) with a crushing blow of force. The tests do have drawbacks, however, as the data is hard to reproduce between different laboratories (some people just hit harder than others). A depiction below displays an impact instrument.

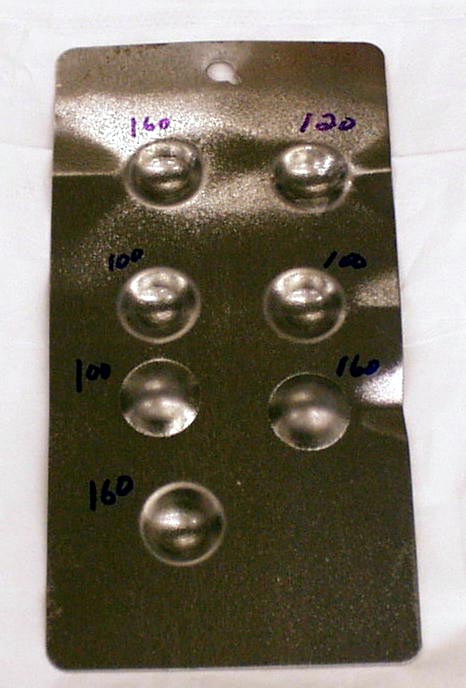

The organic coatings being tested are applied to a suitable substrate such as the metal panel employed in many other ASTM tests. The requires post-cure timing and involves the dropping of a standard weight (lead) a certain distance onto the coating panel. The indention can be either intrusion or extrusion. By gradually increasing the distance the weight drops, the point at which failure usually occurs can be determined. Films generally fail by cracking, which can be made more visible by the use of a magnifier, in the case of the metal substrate, copper sulfate. The test is a good indicator of coatings performance under a huge impact such as automobile accidents and significant weight drops on treated wood (varnished). The results of an actual impact test on a coated panel is depicted below. Notice that the impact points are both concave and convex.