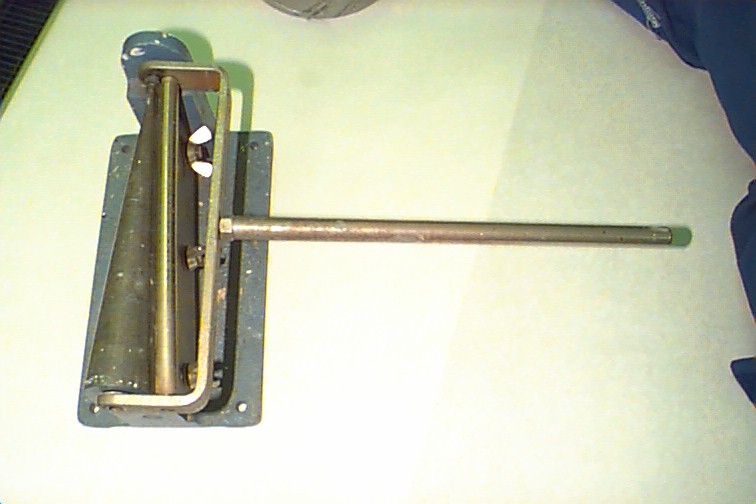

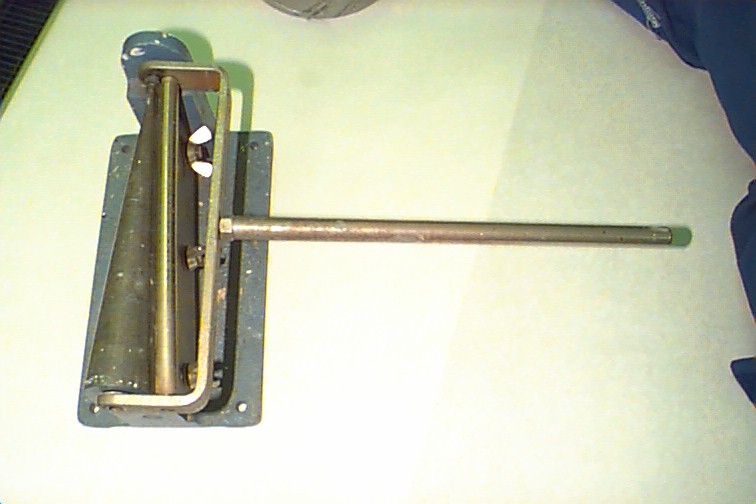

The Mandrel Bend Test covers the determination of the resistance to cracking (flexibility) of attached organic coatings on substrates of sheet metal or rubber-type materials. It is also a perfect chance for the destructive folk reading to learn of a good technique to bend stuff into a morbid state. Just kidding. A Mandrel Bend Test instrument is pictured below. As you can see, a great deal of pain can be potentially caused by the instrument.

The coating materials under test are applied at uniform thickness to panels of sheet metal or rubber materials. After drying or curing the coated panels are bent over a mandrel (above) and the resistance to cracking of the coating is determined. Coatings attached to the substrates are elongated when the substrates are bent during the manufacturing of articles or when the articles are abused in service. These test methods have been useful in rating attached coatings for their ability to resist cracking when elongated. They have been useful evaluating the flexibility of coatings on flexible substrates. Depicted below is a sheet metal panel with a drawn down coating which has been subject to a mandrel test. As one can see, the coating is cracked down the bend of the panel.